Tsis Siv Neeg Wafer Packing Kab L Hom

Lus piav qhia luv luv:

Qhov no tsis siv neeg wafter packing kab yog muaj feem xyuam rau wafer thiab lwm yam zoo xws li tej khoom uas muaj peev xwm loj, tab sis nyob rau hauv kev txiav txim zoo thiab zoo li qub.Nws daws cov teeb meem ib txwm muaj xws li nyob ze ze ntawm cov khoom, cov kev taw qhia nyuaj tig, tsis yooj yim rau kev teeb tsa hauv kab, thiab lwm yam kom ua tiav ib lossis ntau daim ntawv ntim.

Product Detail

Khoom cim npe

Product Detail

Qhov kev ntim khoom tsis siv neeg no yog tsim los rau cov khoom lag luam nrog lub tais lossis lub thawv, thiab cov kab ntim khoom no tuaj yeem tuaj yeem thauj lub tais thiab ntim yam tsis muaj kev tuav haujlwm.

Ib tus neeg ua haujlwm tuaj yeem ua haujlwm tau ob txoj kab, uas yuav pab txuag nqi zog rau cov neeg siv khoom.

Cov kab no pub rau hauv thiab ntim khoom yog nruab nrog deoxidizer lossis deoxidizing tus neeg saib xyuas pad feeder, tais nqus tsev, lub tais tsis siv neeg thauj khoom thiab ntim tshuab.

Lub ntim ceev ntawm lub tais ntim khoom thiab ntim kab yog 100-120 hnab ib feeb.

1. Khoom Taw qhia ntawm Tsis Siv Neeg Kab rov tav Wrapping Equipment rau Swiss Roll

Qhov no wafer ntim system yog ib tug multi-function system, uas yuav ntim ib wafer thiab multi-wafer.Peb tsim tag nrho cov txheej txheem ntim raws li koj qhov kev teeb tsa thiab kev nug.Qhov siab tshaj plaws ceev tuaj yeem mus txog 250 hnab / min.Qhov ceev ntawm tsev neeg pob nyob ntawm qhov loj.

2. Lub luag haujlwm tseem ceeb ntawm lub tshuab ntim khoom noj rau wafer

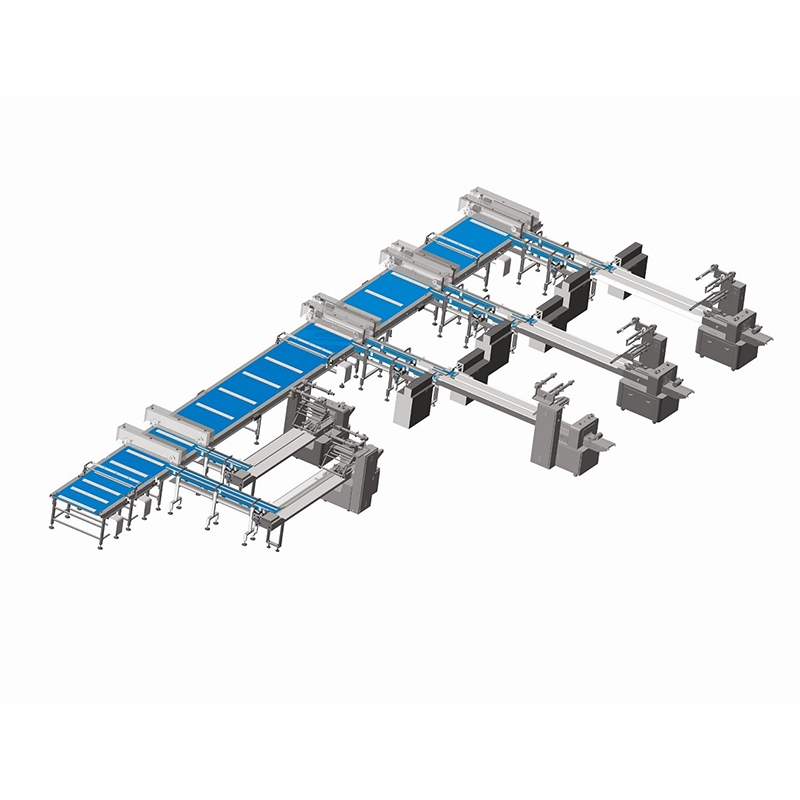

Lub wafer packing kab muaj xws li nyob deb li cas, reversing conveyor, nws pib sorting unit, thiab packing tshuab.Cov txheej txheem no yuav pab wafer pib aligning, nrug, faib, thiab xa mus rau lub sorting unit thiab tiav packing nyob rau hauv thiaj li yuav ua kom ib tug tas mus li thiab kev txiav txim ntau lawm nrog qis pov tseg thiab zoo nkauj pob.Cov tshuaj tsuag dej cawv thiab cua them yog xaiv tau.

Ib kab ntim ceev tuaj yeem ncav cuag 80-220 hnab / min.

Tag nrho cov ntim tshuab txais 220V, 50HZ, ib theem.Tag nrho lub zog yog 26KW

Cov khoom ntim khoom siv tuaj yeem siv cov qauv ntim sib txawv raws li cov neeg siv khoom nug.

3. Qhov zoo ntawm Cov Khoom Noj Tsis Siv Neeg Ntim Tshuab rau Wafer Biscuit

Kab rov tav packing kab nruab nrog nws pib aligning ntaus ntawv thiab tiv thaiv npog.Cov cuab yeej kho nws tus kheej yog xaiv tau.

Cov qauv yooj yim, ua haujlwm yooj yim, tu yooj yim, thiab tu.Kev hloov kho yooj yim rau cov khoom sib txawv lossis cov teeb tsa parameter.

Kev Tswjhwm siv cov khoom siv hluav taws xob zoo, ntse PLC, kov npo, thiab HMI zoo, ua haujlwm yooj yim dua thiab yooj yim dua.

Cov kab ntim ntim tau nruab nrog ntau qhov sib txawv ceev siv los npaj cov ncuav los yog ncuav qab zib kom tau txais kev kub ceev ruaj khov thiab nrhiav kom raug.

Lub tshuab ntim khoom noj tsis siv neeg thiab qhov system siv cov hlau tsis muaj steel thiab Nylon baffle, yooj yim rau kev khiav lag luam thiab tu.

PU siv tuaj yeem tso tawm yam tsis muaj cov cuab yeej hauv 1 feeb thiab nruab nrog lub plhaw kom tau cov khoom pov tseg, uas yooj yim rau kev tu thiab tu.

Cov khoom noj tshuab qauv yog yooj yim heev, ua haujlwm yooj yim, yooj yim rau kev tu thiab tu.Kev hloov kho yooj yim rau cov khoom sib txawv lossis cov teeb tsa parameter.

Kev tswj hwm ntawm cov khoom ntim yas yas siv cov khoom siv hluav taws xob zoo, PLC ntse, kov npo, thiab HMI zoo, ua haujlwm yooj yim dua thiab yooj yim dua.

Peb yuav ntxiv 90-degree tig conveyor lossis 180-degree tig conveyor rau lub ntim ntim raws li cov neeg siv khoom lub Hoobkas tsim lossis qhov chaw.

Nruab nrog lub ntsuas ntsuas ntsuas thiab ntsuas qhov hnyav, uas tuaj yeem txuas nrog lub ntim ntim.

Wafer tsis siv neeg ntim khoom noj tshuab nruab nrog nws pib aligning ntaus ntawv thiab tsis siv neeg kho khoom siv rau txoj siv yog xaiv tau.

Cov kab ntim khoom tuaj yeem kho cov wafers (cov khoom lag luam) thiab xa mus rau qhov chaw sib cais kom tau txais kev kub ceev ruaj khov thiab nrhiav lawv kom raug.

PU siv lub tshuab ntim khoom tuaj yeem tso tawm yam tsis muaj cov cuab yeej thiab nruab nrog hopper kom tau txais cov khoom pov tseg, uas yooj yim rau kev tu thiab tu.

Cov qauv yooj yim, ua haujlwm yooj yim, yooj yim tu thiab tu.Kev hloov kho yooj yim rau cov khoom sib txawv lossis cov teeb tsa parameter.

Lub wafer kab tswj system siv cov khoom siv hluav taws xob zoo, ntse PLC, kov npo, thiab HMI zoo, ua haujlwm yooj yim dua thiab yooj yim dua.

PU txoj siv tawv ntawm cov kab ntim wafer tuaj yeem siv cov ntaub ntawv nplaum nplaum rau xim dawb xaiv.

4. Daim ntawv thov ntawm Tsis Siv Neeg Ntim Machinery

Muaj feem xyuam rau kev ntim cov khoom noj extruded thiab lwm yam khoom tsis tu ncua, uas ua los ntawm cov tshuab txiav.Txuas nrog yav dhau los cov kab ntau lawm los ntawm tsis siv neeg feeder lossis phau ntawv feeder.

5. Ntim Cov Qauv

6. Kev kos duab tsis siv neeg ntim tshuaj

7. Ntim Cov Lus Qhia.

(1) Distance controller

Lub luag haujlwm tseem ceeb ntawm tus tswj kev ncua deb yog rub hla cov khoom nyob deb lossis khaws cia rau hauv kab.

(2) Distributor conveyor

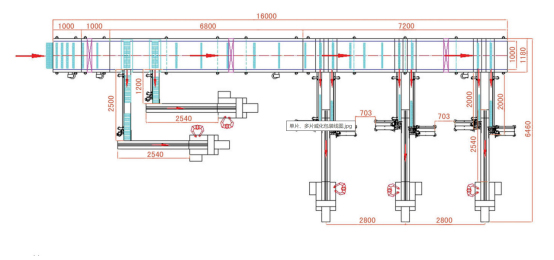

Qhov kev faib tawm conveyor ntawm cov tshuaj ntim khoom no yog siv los xa cov khoom rau hauv cov kab ntim sib txawv.Qhov ntev ntawm cov khoom no nyob ntawm cov neeg siv khoom lub peev xwm ntau lawm lossis lub Hoobkas tsim.

(3) Kev taw qhia pusher

Cov kev taw qhia pusher ib txwm tsuas yog siv rau wafer ntim system, uas pab hloov cov kev taw qhia wafer thiab xa mus rau lub tshuab ntim sib txawv.

(4) Txoj siv sia cia

Lub luag haujlwm tseem ceeb ntawm txoj siv sia cia yog khaws cov wafers thiab pab xa mus rau lub tshuab ntim khoom, ntim tiav.

(5) Servo pusher

Taw qhia: Lub servo pusher no tsuas yog siv rau tsev neeg wafer ntim kab.Hauv cov lus txiav txim, yog tias koj xav tau 6pcs ib lub hnab (2 txheej thiab txhua txheej 3 daim), ces qhov no yuav tsum tau xaj.Yog tias koj tsuas yog xav tau ntim ib qho wafer, ces tsis xav tau cov khoom no.

Function: Lub luag haujlwm tseem ceeb yog thawb cov pab pawg wafer rau hauv cov khoom siv thauj khoom, tom qab ntawd pob.

(6) sorting unit

Sorting unit ntawm ntim system qhia:

Lub sorting chav tsev yog muaj 2 conveyor siv thiab 5-6 sensors.

Lub luag haujlwm ntawm sorting unit:

Lub luag haujlwm tseem ceeb ntawm qhov kev txheeb xyuas no yog tswj xyuas cov khoom noj ceev, nyob ntawm nws, thiab txuas nrog lub tshuab ntim khoom.Thaum nws pom cov khoom ntau dhau lawm, kev pub mis yuav qeeb, yog tias tsis muaj cov khoom, ces qhov kev pub mis yuav hais sai sai.

Qhov zoo ntawm lub sorting unit:

Txo kev ua haujlwm ntawm tib neeg thiab ua kom lub tshuab ntim khoom khiav ntawm qhov nrawm nrawm nrog cov khoom siv tsawg dua.