TMZP100 Flow Wrapper Pillow Packing Tshuab

Lus piav qhia luv luv:

Qhov no flow wrapper hauv ncoo packing tshuab yog siv rau ntim ntau yam khoom tsis tu ncua, xws li biscuits, ncuav qab zib, ice pops, daus ncuav mog qab zib, chocolate, khoom qab zib, tshuaj, soaps tsev so, khoom txhua hnub, hardware parts thiab hais txog.

Hauv-feed ib feem tuaj yeem kho raws li qhov xav tau tiag tiag.

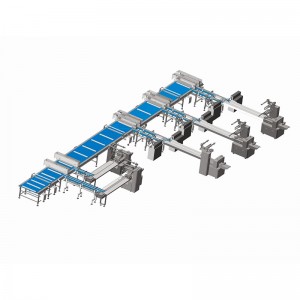

Nws tuaj yeem sib txuas lus nrog cov tshuab sab saud thiab hauv qab yog tias xav tau.

Product Detail

Khoom cim npe

Technical Parameters

| Qauv | TSW-100 |

| Ceev | 35-220 pcs / min |

| Hnab loj | (L) 65-200mm (W) 30-90mm (H) 5-30mm |

| Zaj duab xis dav | 65-220 hli |

| Cov khoom siv zaj duab xis | OPP / CPP PT / PE KOP / CPP ALU-FOIL |

| Dimension | (L) 4000mmX(W)850mmX(H)1600mm |

| Lub zog kub | 2.4 kW tsi |

| Lub cev muaj zog | 0.6 kWm |

| Tag nrho lub zog | 3 kW |

| Tag nrho hnyav | 5 50kg |

TMZP-100 Kab rov tav ntim tshuab nrog kev kub ceev thiab CE

1.Product introduction

Lub tshuab ntim ntim dej no yog thawj tus qauv tsim nrog 220 hnab ib feeb ruaj khov ceev, tsim rau cov khoom me me, xws li ncuav mog qab zib, biscuit, cov ntaub so ntswg, khoom siv kho mob.

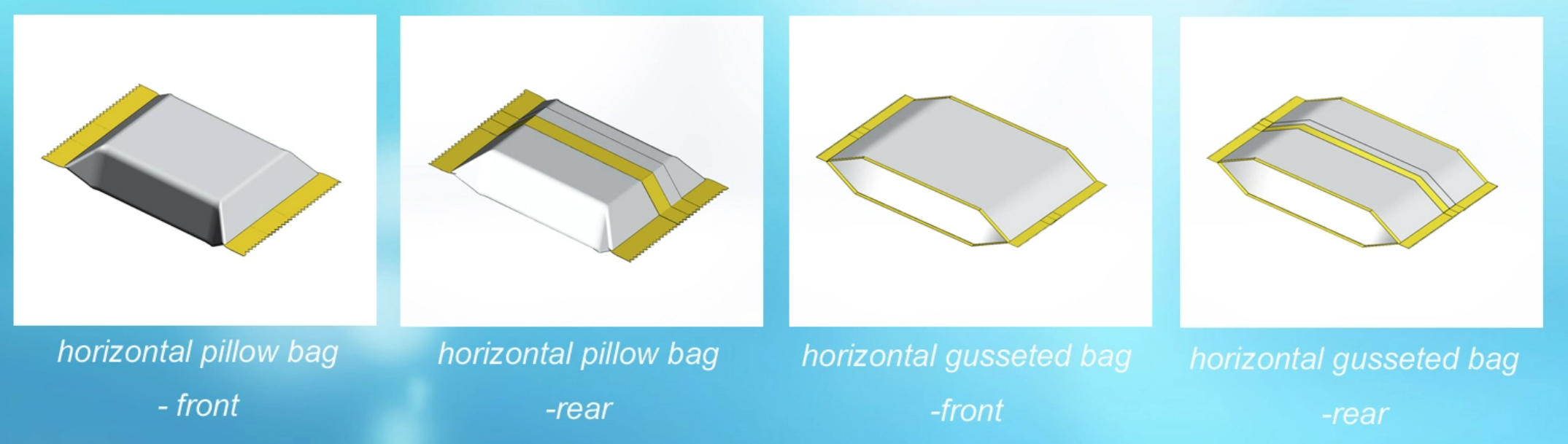

Tsis siv neeg tshuab rau kev tsim khoom siab. Kab rov tav packing siv ib zaj duab xis coil nrog peb weldings: ob tug ntoo khaub lig-weldings thiab ib tug longitudinal vuam. Hom tshuab ntim khoom no yog tsom rau cov khoom noj khoom haus thiab cov khw muag khoom noj.

2. Cov yam ntxwv thiab cov qauv tsim

(1) Tsis siv neeg tshawb xyuas thiab teeb lub hnab ntev yam tsis muaj kev teeb tsa ntawm cov khoom ntim khoom kov npo

(2) Cov qauv tshuab yooj yim nrog lub log hloov tau yooj yim, yooj yim los tswj lossis hloov qhov chaw. Nws lav lub neej ntev ntev thiab tu cev.

(3) Tib nti ntawm lub ntsiab tswj Circuit Court tsim los ntawm peb lub tuam txhab. Cov tshuaj ntsuam digital thiab transducer tswj tau lav ua haujlwm yooj yim

(4) Ob chav transducer tswj nrog stepless hloov ceev thiab dav hloov, Nws tuaj yeem ua tau zoo nrog cov txheej txheem ua haujlwm qub ntawm cov kab ntau lawm;

(5) Cov khoom siv tau zoo heev tau txais thiab saib xyuas tag nrho cov txheej txheem ntim khoom.

(6) Kev tswj qhov kub thiab txias tuaj yeem lav cov pob khoom zoo nkauj thiab nruj.

(7) Tsim nyog rau ntau yam ntawm cov khoom ntim hloov tau yooj yim, ntim loj thiab cov khoom lag luam.

(8) Cov cuab yeej xaiv tau: lub tshuab luam ntawv hnub tim, lub tshuab hluav taws xob cua thiab servo motors

(9) Lub tshuab nrog cov qauv tsim, zoo tagnrho rau kev tsim khoom me me.

(10) Cantilever tsim cosntruction kom optimize lub tshuab huv si thiab tu.

(11) 2.5 m ntev infeed conveyor rau ntim khoom.

(12) Sab saum toj reel tuav nrog self-centring reel fastening thiab braking system.

(13) Peb khub ntawm rollers rau rub zaj duab xis thiab cov ntsaws ruaj ruaj ntev.

(14) Tig lub puab tsaig sealing taub hau nrog qhov siab tshaj plaws.

(15) djustable infeed suab rau ntau yam khoom

(16) Mechanic gearbox los kho lub hnab ntev

(17) Toothed ncej rau configured raws li cov khoom ntev

(18) Kev nyab xeeb npog nrog kev ruaj ntseg micro-switches

(19) 54 hli tawm-piv txoj siv / tiav siv ntawm cov khoom ntim

(20) Kev tswj qhov kub thiab txias, intuitive zaub, yooj yim rau kev teeb tsa, qhov kub thiab txias

3. Kev xaiv khoom siv ntawm cov khoom ntim khoom

(1) "Tsis muaj khoom - Tsis muaj lub hnab" muaj nuj nqi.

(2) Ntxiv 'meter' ntawm pub conveyor.

(3) Photocell rau centering luam tawm zaj duab xis.

(4) Ob chav reel tuav.

(5) Hnub tim code printers.

(6) Gusseting ntaus ntawv.

(7) Zig-zag txiav riam.

4. Ntim Tshuab Cov Lus Qhia Taw Qhia:

A.Spool yas dhos / Zaj duab xis tiag txhawb txog lub tshuab ntim khoom

Lub spool tuav yog nws tus kheej-center thiab tso cai rau yooj yim zaj duab xis spool hloov

Tsis siv neeg muab ob npaug rau spool-tswj muaj nyob rau hauv kev xaiv ntxiv yog tias tsis tau teeb tsa daim ntawv thov

B.Seal log txog lub tshuab ntim khoom

Lub tshuab hluav taws xob tiv thaiv yuav pab kom tsis txhob hlawv cov yeeb yaj kiab, txawm tias lub tshuab tsis ua haujlwm

Lub kaw lus tswj hwm los ntawm kev tswj hwm qhov kub thiab txias nrog ob lub vijtsam HMI rau kev kho cov asynchronies thiab txo qhov tsis sib xws rau +/-2 ° C

Lub rollers kuj system yog qhib los ntawm cov khoom hauv lub xeev relays

Kev tswj qhov kub thiab txias muaj ntau lub tswb ceeb toom rau cov neeg ua haujlwm ceeb toom yog tias muaj teeb meem tshwm sim

Greasing cov ntsiab lus yog centralized rau kev kho yooj yim

Txoj kev tsim qhov yog universally adjustable rau qhov siab thiab dav

C.Head-cutter txog lub tshuab ntim khoom

Ib qho yooj yim siv hluav taws xob khawm ntawm HMI yog siv los tso cov khoom nrog lub taub hau-cutter

Kev tswj qhov kub thiab txias yog nruab nrog ntau lub tswb ceeb toom

Cov hniav txiav yog tag nrho adjustable

Greasing cov ntsiab lus yog centralized rau kev kho yooj yim

Cov qauv ntawm cov pab pawg yog coated steel thiab cov ntsiab lus kub yog mechanically sib cais nyob rau hauv thiaj li yuav tso cai rau zoo heev kub dispersion

Lub siab dampener yog adjustable los ntawm ob springs

Lub tshuab tau nruab nrog cov cuab yeej kev nyab xeeb los tiv thaiv kev puas tsuaj rau cov tshuab. rhiab heev tuaj yeem hloov kho raws li cov khoom

Cov tswj tso cai rau qhov sib txawv ntawm qhov dav thiab qhov siab ntawm cov khoom

D.Control Vaj Huam Sib Luag

E.IN-FEED CONVEYOR

Cov khoom noj hauv cov khoom noj muaj tag nrho ntev ntawm 2.5 meters thiab nta stainless hlau lateral qhia uas tuaj yeem qhib tau yooj yim thiab ntxuav. Ib qho kev xaiv nyob rau hauv-feed conveyor uas yog 1000-3000 mm kuj muaj.

Cov rub tawm uas tshem tau yog tsim los ntawm cov yas zoo thiab muaj ntawv pov thawj rau kev siv nrog cov khoom noj

Cov khoom yog thauj los ntawm Teflon mats kom tsis txhob muaj kev puas tsuaj

Qhov qhib hauv qab ntawm cov khoom noj khoom haus yog hinged kom yooj yim rau kev ntxuav

Zaub